15.09.2025 20:37

Ballast Water Treatment System – A Boon For Many, A Menace For Some

I still remember the day when I joined my maiden vessel more than a decade ago. A Supramax bulk carrier with the least automation and the most troubles. I was welcomed by a lot of judgemental yet uncaring eyes.

A new Cadet is on board! To add some spice to it, he’s a first-timer and presumably stupid; An old and tough Soviet Chief Officer who’s pissed because he couldn’t sign off in the last port.

Rain poured down the sky, and the day couldn’t get gloomier beyond imagination. I was shown my cabin and asked to change and to report immediately to the Training officer, who didn’t give a damn about who or where the trainee was. Without looking at me, he asked me to take the sounding of the tanks using a sounding rod tied to a rope, already drenched in the water. If a nightmare is a reality, this is it. With no one to supervise or demonstrate, I somehow could give the approximate sounding of the ballast tank I was asked to check.

Next, after the sounding, “Go do the line setting of the Forepeak tank in the Engine room”. Setting the lines was a far-off fantasy, and I didn’t even know the way to the Engine Room. Yeah, those were the days, and such were the challenges in those days. Yes, if you ask today’s Chief officers who were cadets or junior officers, then they would undoubtedly say, “Those were the days”. The primary concern in port operations was Cargo, and the junior officers and cadets would take care of the Ballast operations (mostly).

Today, as a Chief officer and the Ballast water management officer, I face other distinct challenges if we talk about Ballast operations.

It isn’t the case that we didn’t think about the environment back then. To prevent the transfer or introduction of pathogens or aquatic organisms from the source port State to the destination port State, IMO laid down guidelines for the implementation of Ballast water management and Sediment control on board ships in the form of the International Convention for the Control and Management of Ship’s Ballast Water and Sediments (BWM Convention), which was adopted in 2004 and entered into force on 8th Sept 2017. The purpose of the Ballast Water management system is to minimise the risk of transplanting harmful aquatic organisms and pathogens from the ship’s ballast water and associated sediments.

Ways to Compy With Ballast Water Regulations

There are broadly two ways in which we can comply with the regulations.

First is the conventional Ballast Water exchange, and the other is the Ballast Water treatment system.

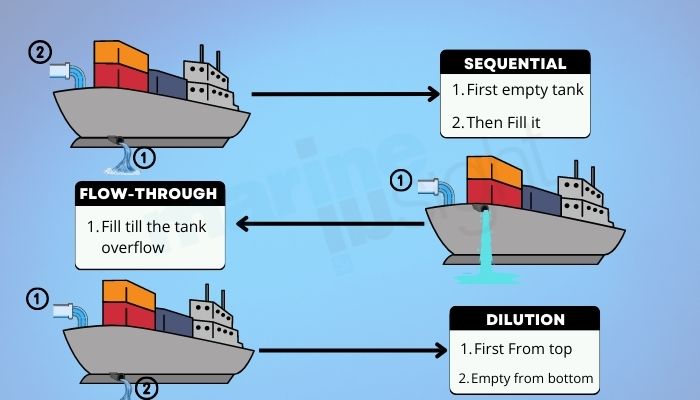

The former has been in practice through ages and is carried out in three ways:

1. Sequential method

2. Flow Through method

3. Dilution method

The Ballast Water Convention requires that the vessel should conduct ballast water exchange :

At least 200 nm from the nearest land and in water at least 200m in depth; if this is not possible, then as far as possible from the nearest land, and in all cases, at least 50nm from the nearest land and in water at least 200m in depth, or sea areas designated by the port state.

The standards mentioned above are categorised in the D-1 Standard of Ballast Water Management.

Now let’s talk about the elephant in the room, the Ballast Water Treatment system.

As per the regulations laid down in the BWM Convention,

Any type of approved ballast water treatment system shall discharge :

Capacity discharge for organisms:

< 10 viable cells/m3 for plankton < 50 μm

< 10 viable cells/mL for plankton between 10-50 μm

< 10 Colony Forming Unit/ 100 mL for Toxicogenic Vibrio cholerae

< 250 Colony Forming Unit/100 mL for Escherichia Coli

< 100 Colony Forming Unit/100 mL for Intestinal Enterococci

BWTS must have a type approval certificate and must be approved by the Administration.

The aforementioned standards constitute the D-2 Standard of Ballast Water Management.

So, the ships with the Ballast Water Management system complying with both the D-1 and D-2 standards can carry out the Ballast Water Exchange and can also use the Ballast Water Treatment system. On the other hand, if a ship complies only with the D-2 standards, she can only use the BWTS for ballast operations and is therefore not allowed to carry out Ballast Water Exchange.

However, there are a few exceptions ( Such as the Safety of the Ship in Emergency situations, Accidental discharge, for the purpose of avoiding pollution incidents, etc.)

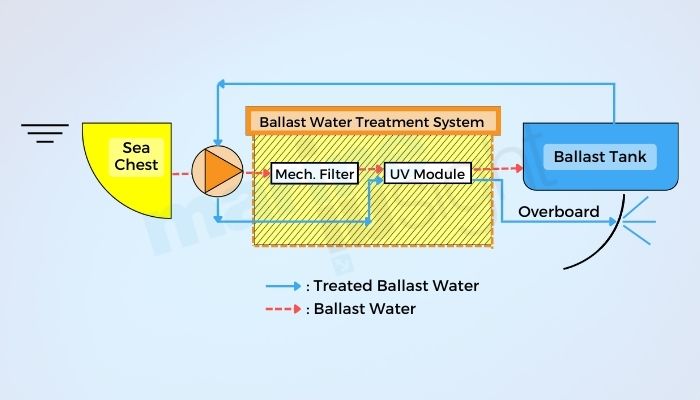

A water filter is normally used in conjunction with another method, such as the ones discussed below. First, filters help to remove sediment, which can be taken in at turbulent ports and, if not properly removed, can accumulate in the ballast tanks. Also, a filter can remove a substantial portion of the micro-organisms. This reduces the time and energy required to neutralise the organisms that may enter through the filter and therefore need to be treated before the water they live in can be stored on board or dumped.

7 types of filtration processes used around the world

UV Systems

Chemical Treatment

Ultrasonic or Cavitation Treatment

Magnetic Field Treatment

Deoxygenation

Heat Treatment.

Electric Pulse and Pulse Plasma Treatments

The most widely used methods are the UV system, the Chemical treatment system and the Ultrasonic system. I have only encountered the UV system BWTS, and the ones who have seen the other systems vouch for the fact that the UV system is one of the most effective and hassle-free systems to be used. We’ll discuss the UV BWTS system further.

CONCERNS regarding the BWTS systems

The first and foremost concern which I personally feel as a seafarer and the Ballast Water Management Officer is that when any regulation is formulated and enforced by the IMO or other concerned Organization, does it take into consideration the factors which are not in the control of the entities directly affected by that regulation or convention. For e.g., We as seafarers are duty-bound to comply fully with the provisions of the Ballast Water Management System but is the Port State in which the vessel is operating in any way accountable for the fulfilment of that regulation?

Ignoring for a while the issues faced because of the substandard quality of the components of the BWTS system or the untimely breakdown of the BWTS system, the exposure of the vessel to the heavily turbid or muddy waters in the port where the vessel is berthed is a major issue. As a Chief officer, my primary concern is whether I would be able to ballast even half of the quantity I’ve planned to.

And if you push it further and stress the system, the filter gets choked ( in one case, the filter element suffered serious damage ), and the system gives away. Time in such cases becomes crucial because stoppage of the cargo operations from the vessel’s side for ballast operations can create a lot of ruckus, commercial losses and intense cross-questioning from the stakeholders.

20.05.2025 12:50

Estonia Grants First Ever Building Permit For An Offshore Wind Farm

18.05.2025 12:00

International Day for Women in Maritime: An Ocean of Opportunities

14.02.2025 10:41

US aircraft carrier collides with merchant ship near Egypt

14.01.2025 22:30

Oil Shipping Rates Surge After US Sanctions Hit Availability

14.01.2025 22:19

Details of Azerbaijani vessels' detention in Africa revealed

25.11.2024 02:15